We provide a full range of sheet metal manufacturing services, including laser cutting, bending, stretching, welding, and assembly, enabling the rapid production of complex sheet metal components

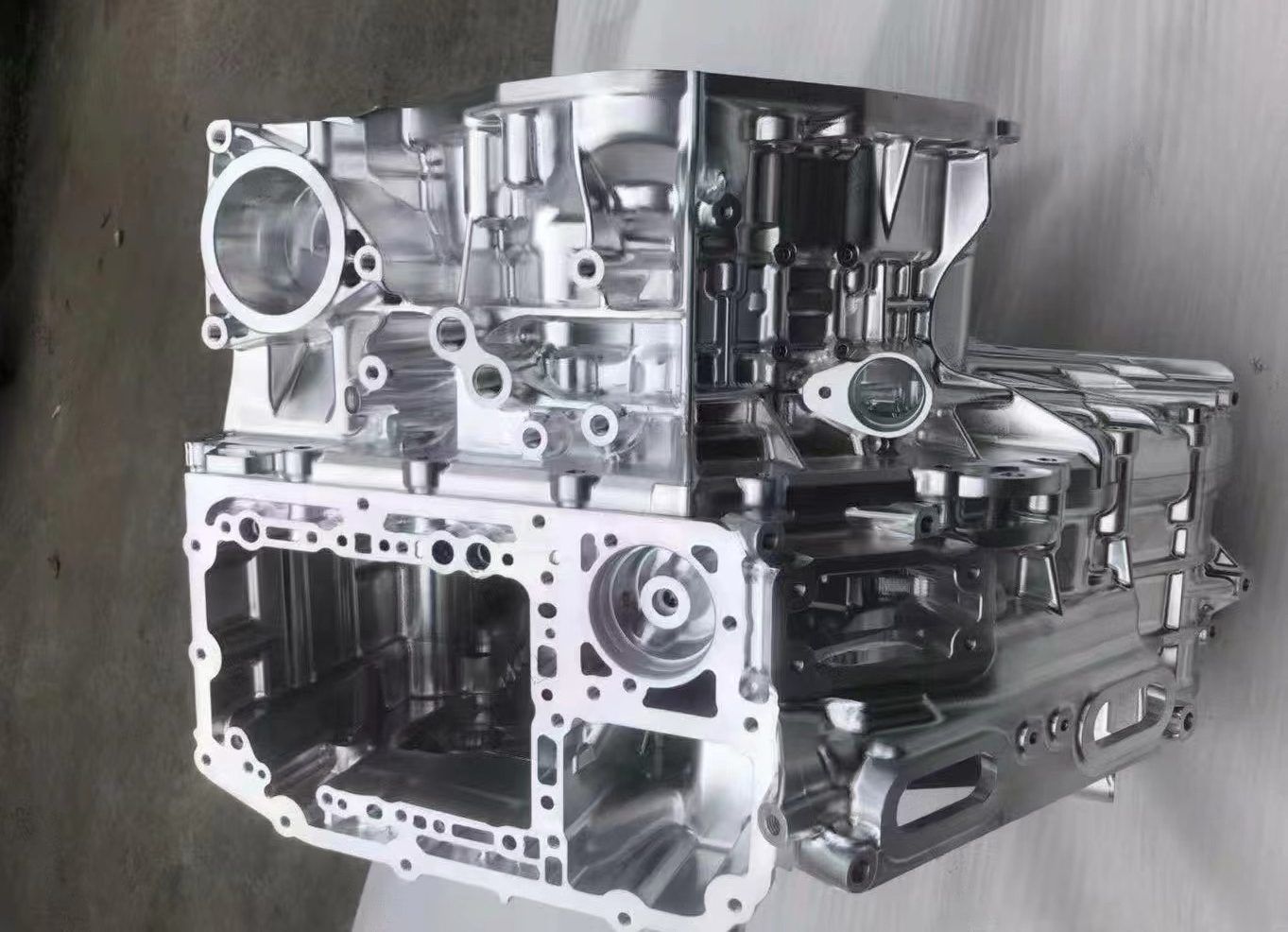

Survey Report on China’s CNC Machining Services

Market Overview of CNC

I hope to receive a more favorable price

⭐⭐⭐⭐⭐

I had a small batch of CNC parts customized and received them promptly. The impression I got from your service was that it offered great value for the cost. However, I’m looking to place larger orders in the future and would appreciate it if you could offer me a discounted price while maintaining excellent quality. Thank you.